Phoenix

Semi-automatic Casemaker

Gluing and turning-in machine to produce hardcovers for books, photo-books or photo-album.

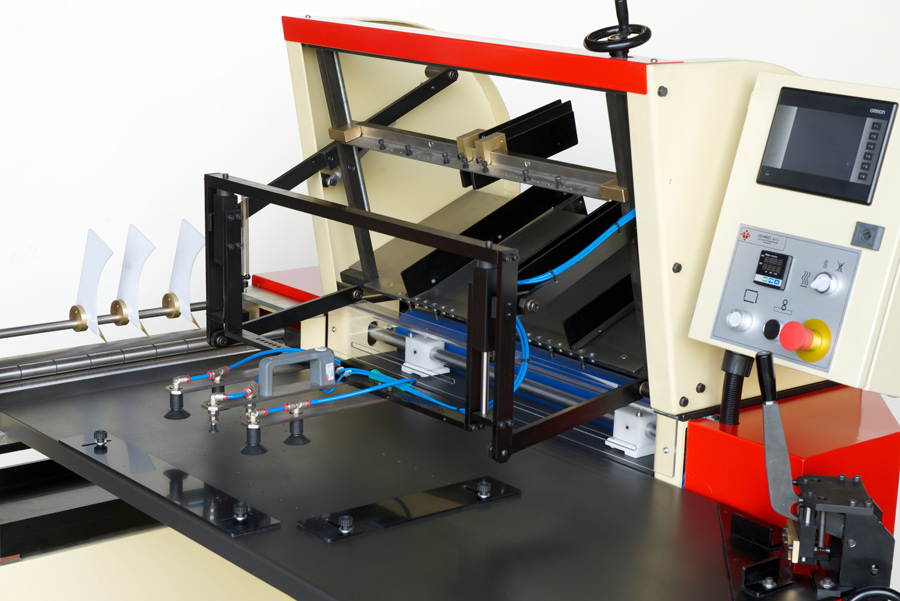

Composed by four distinct units and grouped into a single compact production system:

- Corner cutting unit, for the preparation of the material to be glued. It can cut the corners of the paper with 45 degrees fixed angle and it can cut the cardboard roll to produce the spines.

- Gluing unit that can use hot and cold glue. Special rollers allow to spread the glue evenly on the paper. Equipped with a resistor for heating the glue, connected to a digital controller for setting the temperature.

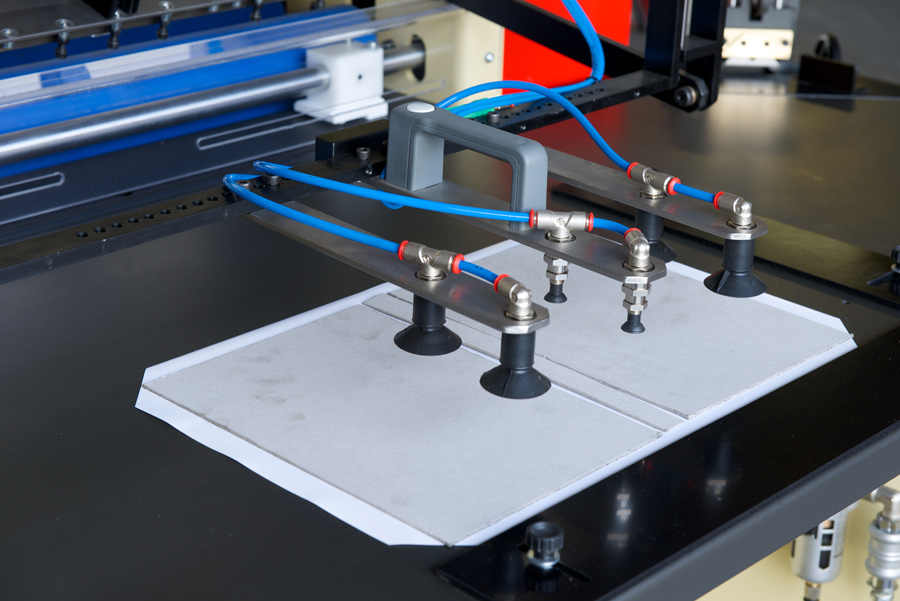

- Cardboard feeder unit, where the three pieces that form standard cover are positioned up to 30 cm maximum height of the stack. Through special suckers the cartons are taken from the feeder and positioned on the pasted material at perfect register.

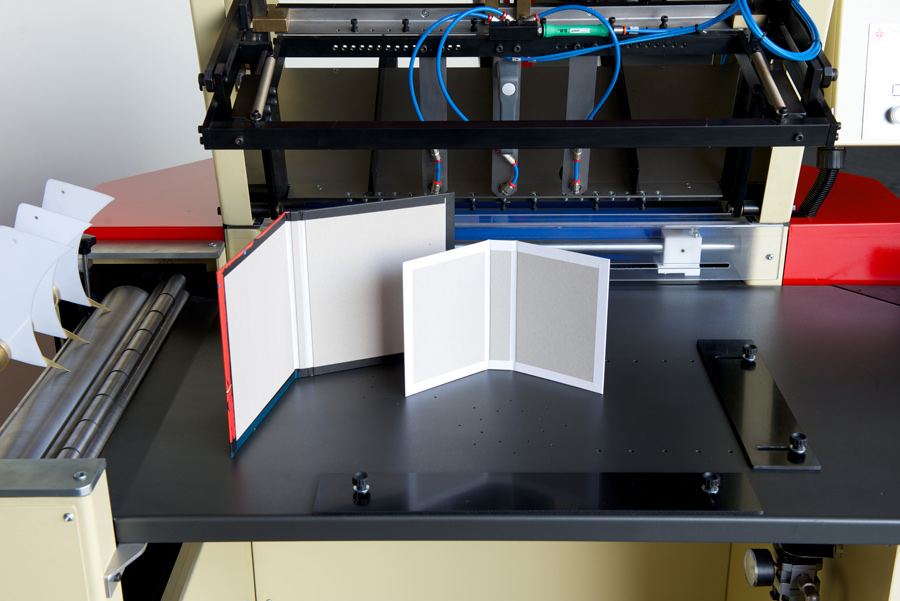

- Turning and pressing unit, driven by a brushless motor and programmed with a touch-screen panel. After coupling the material is pushed into special rubber rollers for automatic turning-in, getting covers perfectly tucked.

Phoenix can produce one-piece covers, three-pieces covers (standard version), four-pieces and five-pieces covers (on demand).

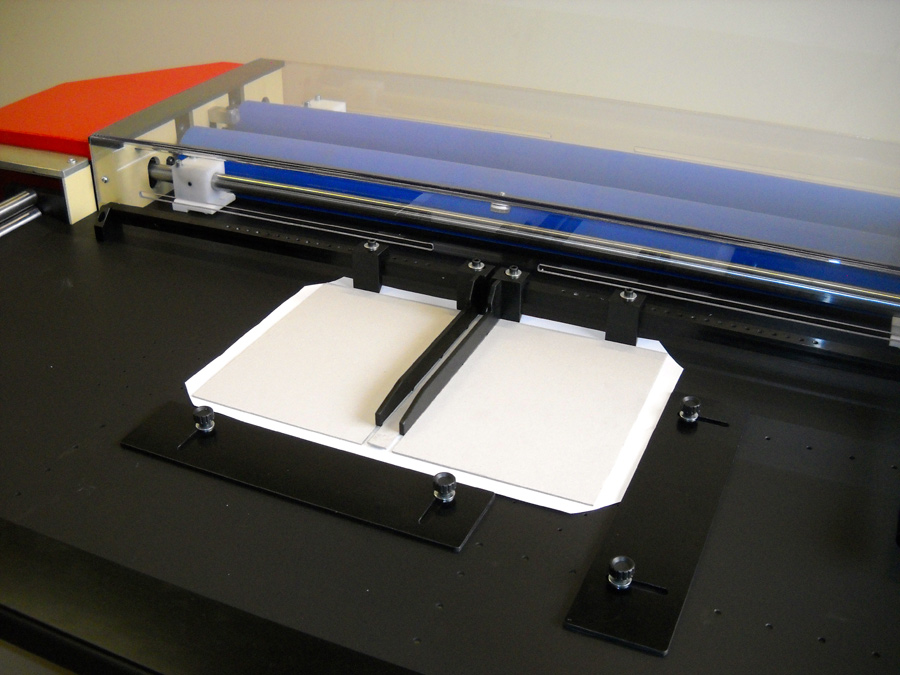

A different version Phoenix SM, suitable for short runs, does not have the cardboard feeder, but is equipped with a special device for manual positioning of the cardboards, particular guides allow to position the material easily and perfectly.

| Phoenix | |

|---|---|

| Cover size max. | 700 x 350 mm |

| Cover size min. | 140 x 140 mm |

| Cardboard thickness max. | 3 mm |

| Cardboard thickness min. | 1.8 mm |

| Turn-in size min. | 18 mm |

| Type of glue | hot and cold |

| Glue feeding | no stop |

| Tank capacity | 6 kg |

| Paper to be glued size max. | 520 x 800 mm |

| Electrical supply | 400 V – 50 Hz – 3 ph |

| Power requirements | 3.5 kW |

| Air consumption | 130 Nl/min at 6 bar |

| Dimensions L x W x H | 175 x 120 x 160 cm |

| Net weight | 500 kg |